I Designed A 3D printed Biomimetic Robotic Hand That Received 1st Place In The 2017 Stratasys Extreme Redesign Competition

2017

Update: I am thrilled to announce that my project clinched the first place in the 2017 Stratasys Extreme Redesign competition! You can check out the winning design on GrabCAD: Biomimetic Robotic Prosthetic Hand.

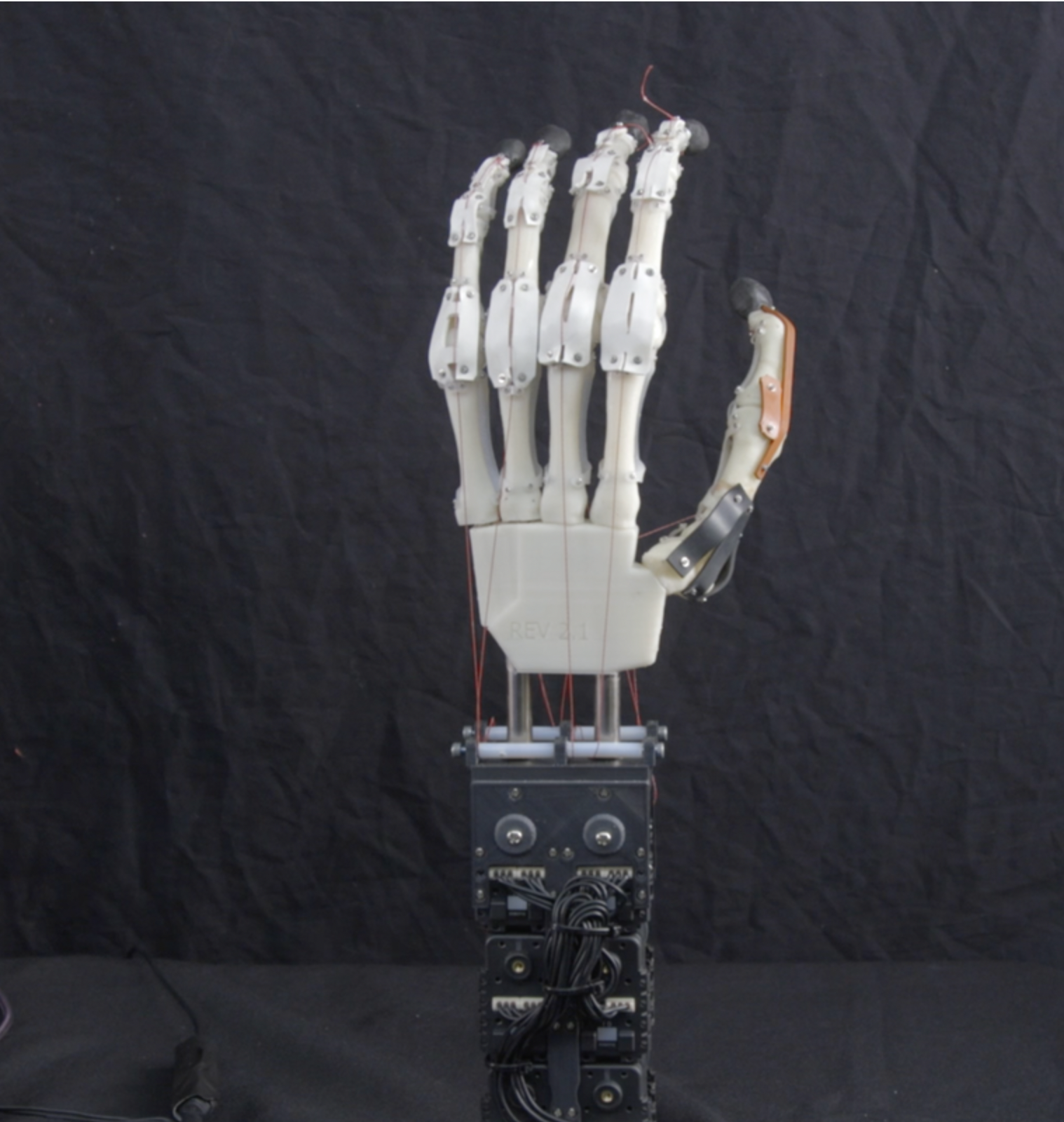

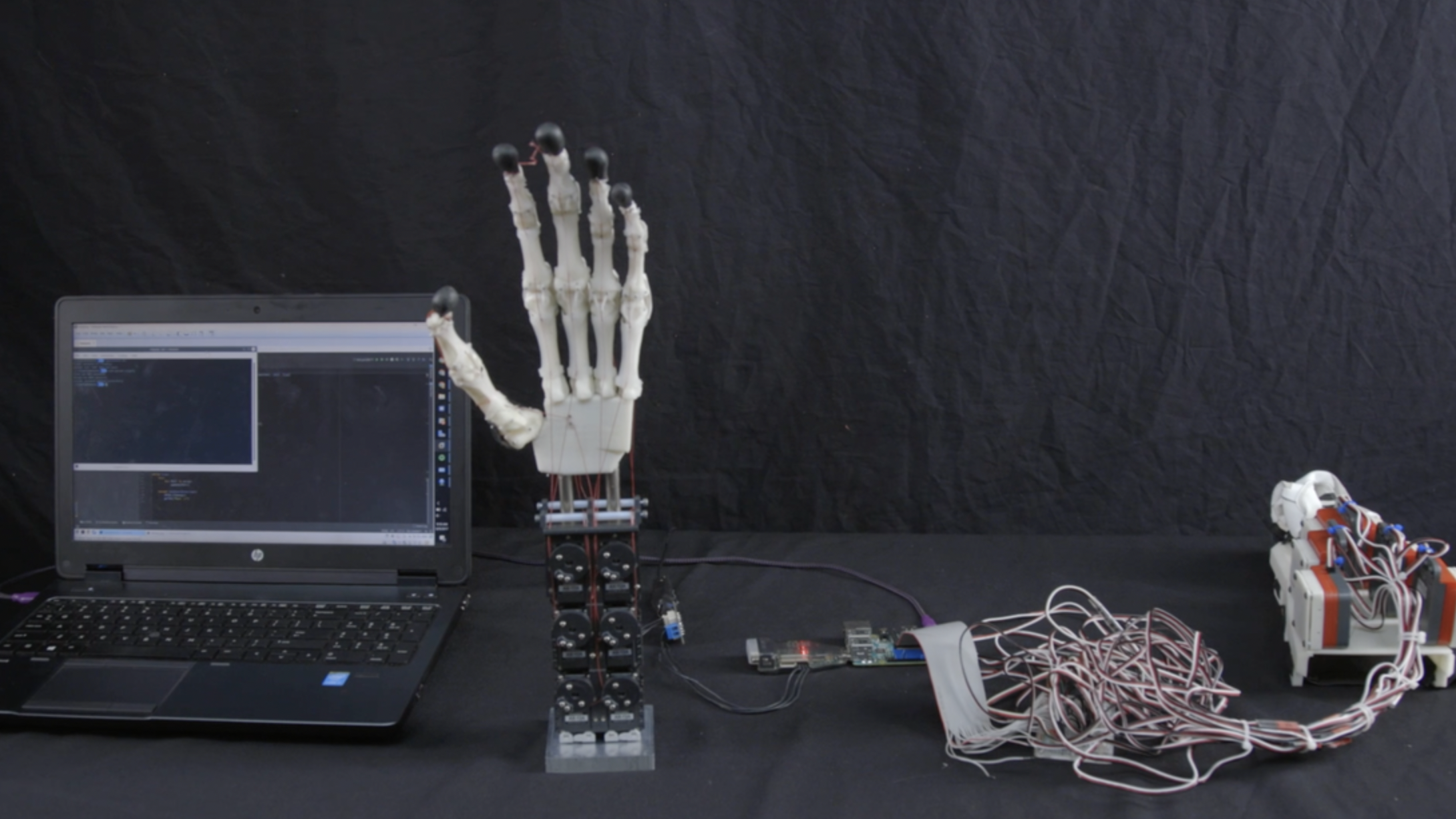

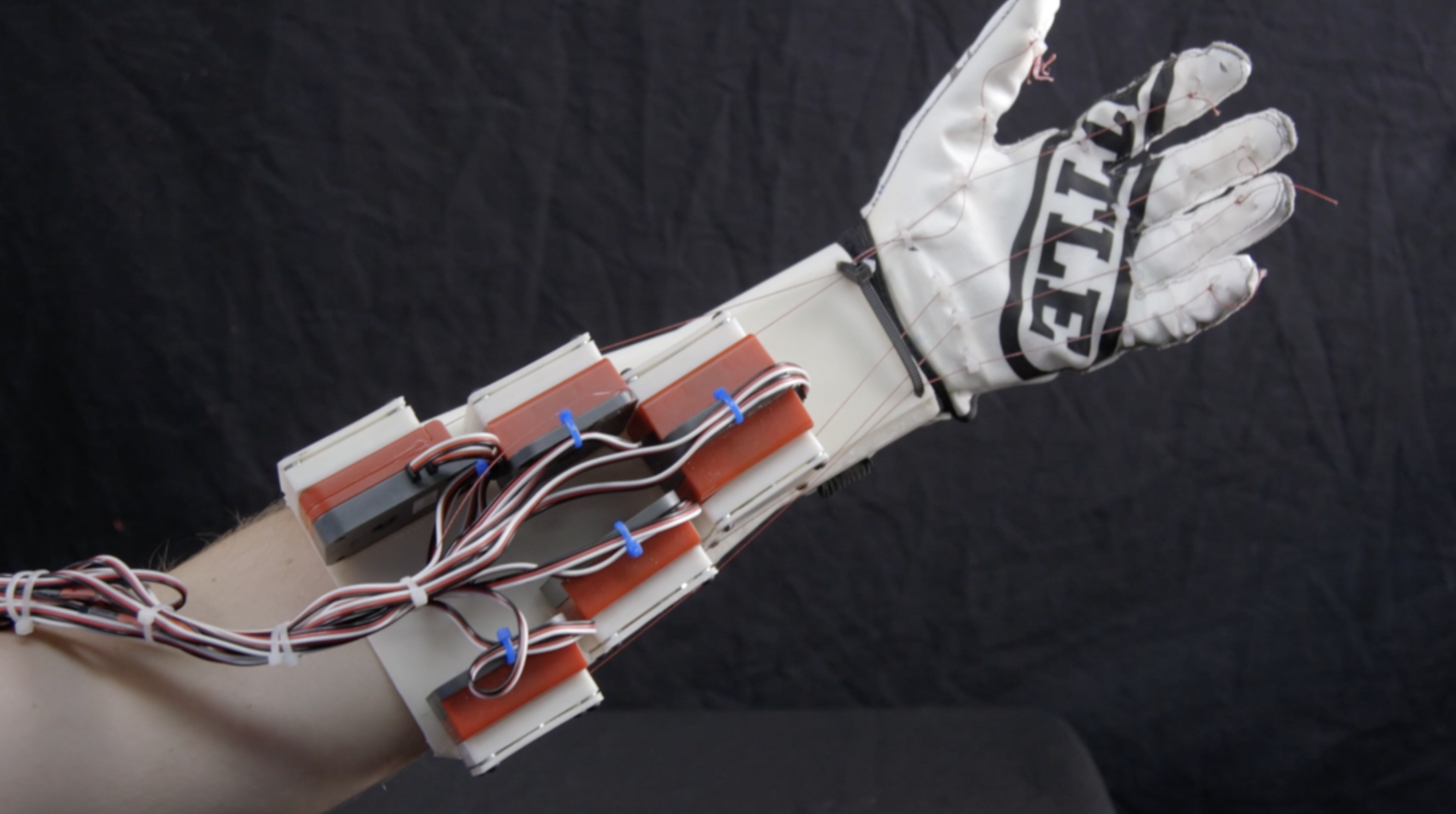

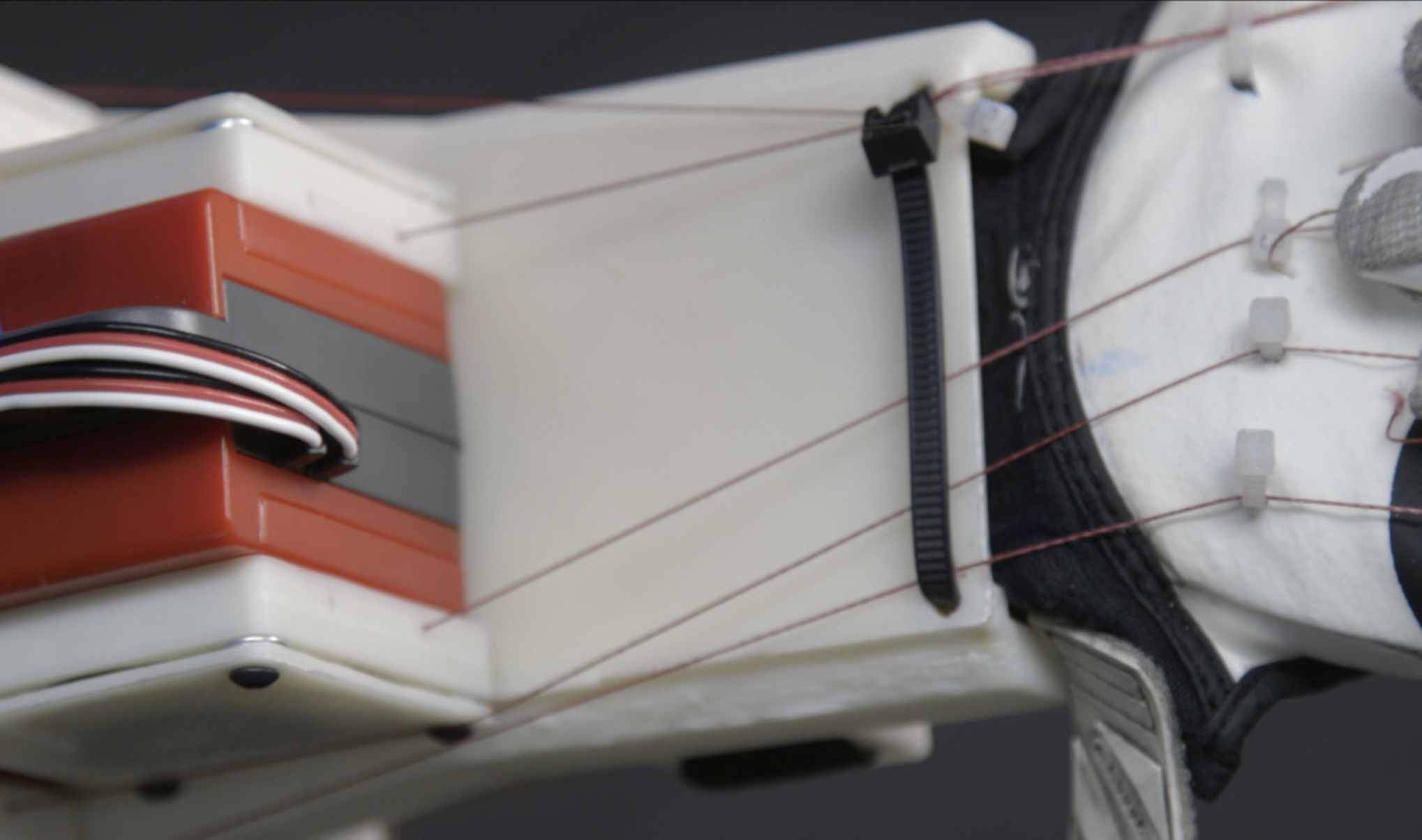

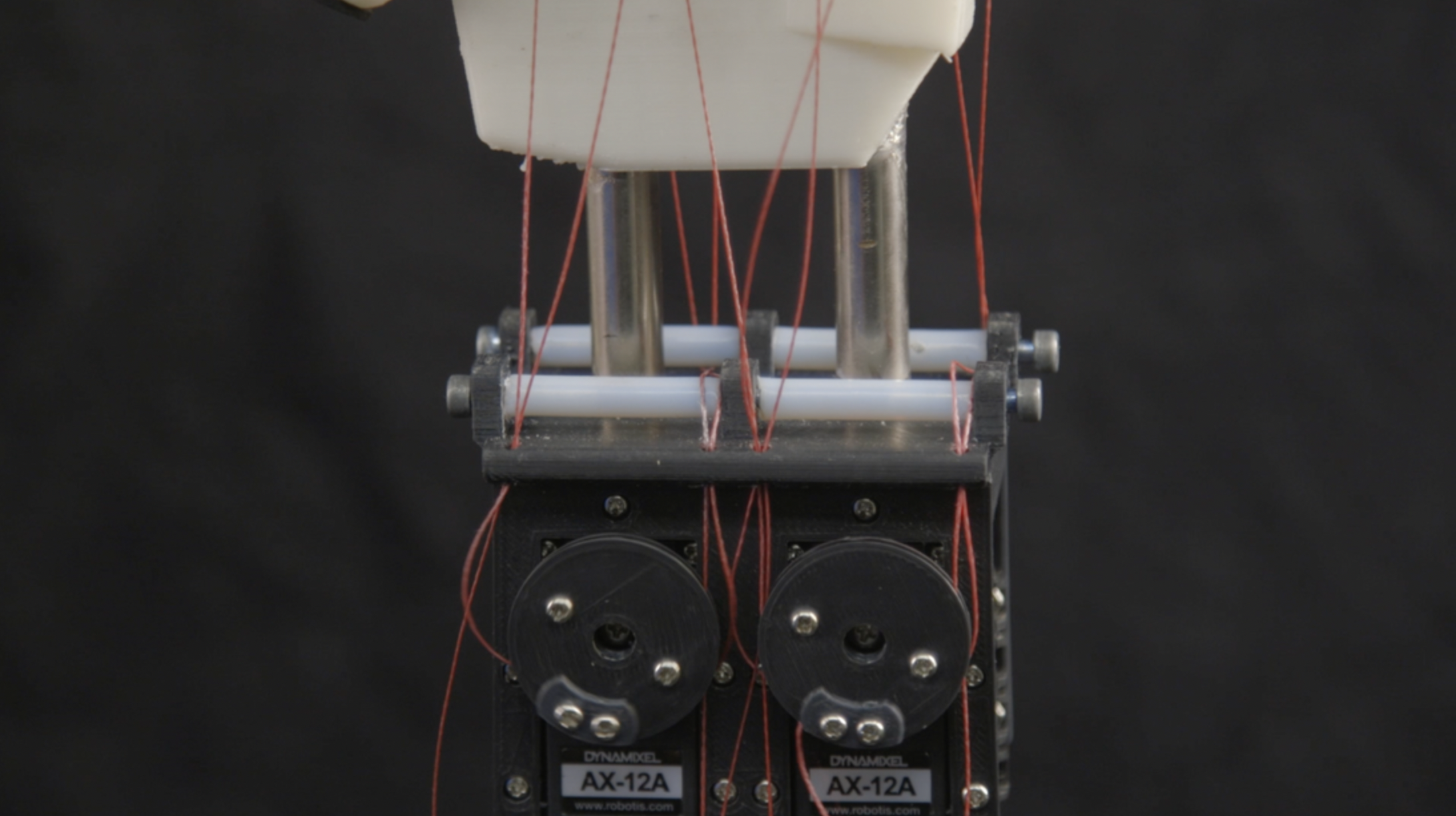

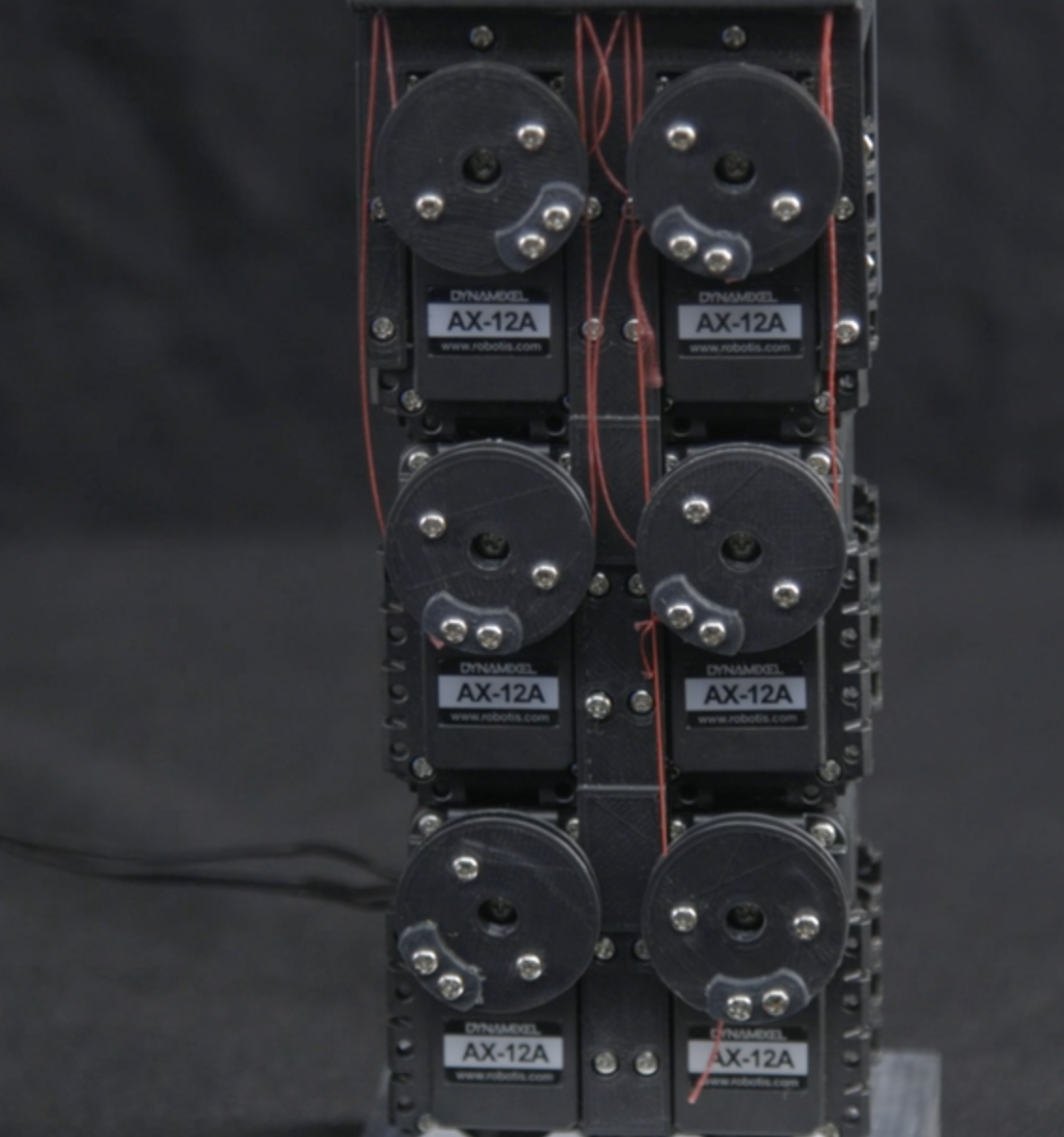

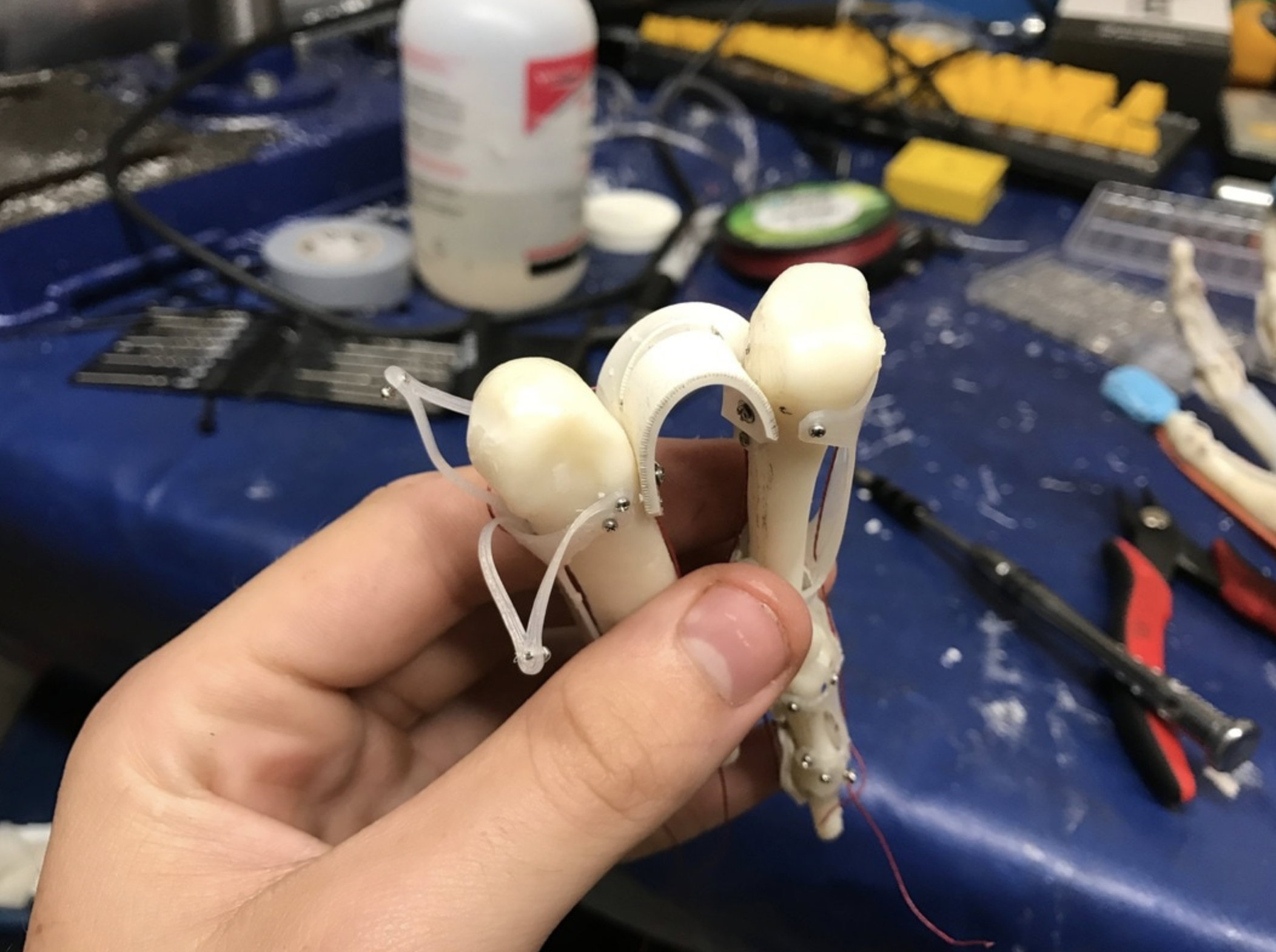

I designed and built a biomimetic robotic prosthetic hand, crafted entirely through 3D printing technology. The hand is a sophisticated blend of 3D printed bones, ligaments, tendon sheaths, and supporting structures such as the palm and servo tower mounting pieces. One of the unique aspects of my design lies in the integration of both rigid and flexible materials, carefully balanced to mimic the complexity of the human hand.

Over the course of a year, I meticulously crafted 54 distinct STL files, comprising 20 bones, 14 tendon sheaths, 16 ligaments, 20 tendon guides, 1 palm, 2 servo mounting plates, 6 pulleys, and 1 carpal tunnel. Among these files, I personally designed 37, while the remaining 20 underwent substantial modifications from their original form, tailored to fit seamlessly into my project. For those interested in the initial files, you can find them here.

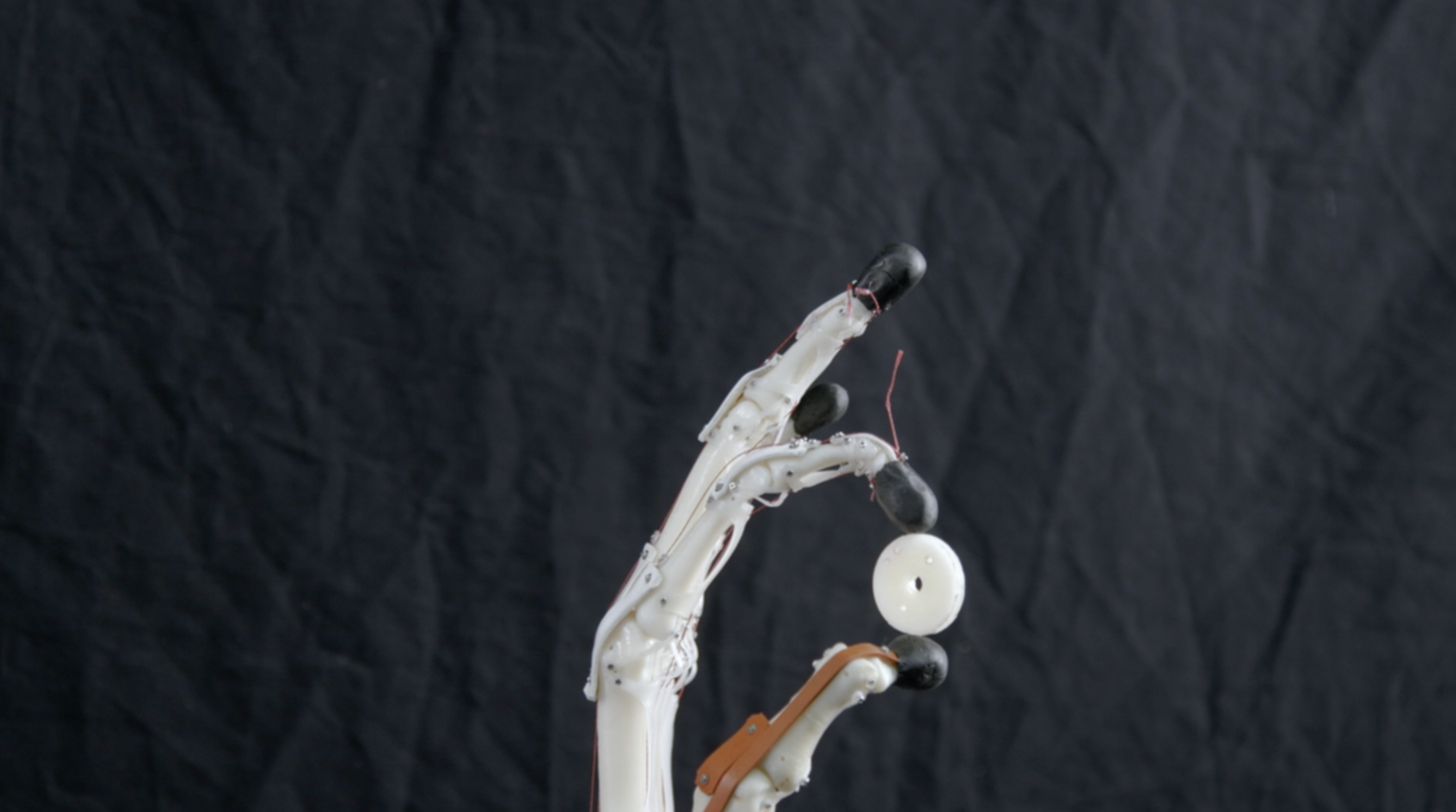

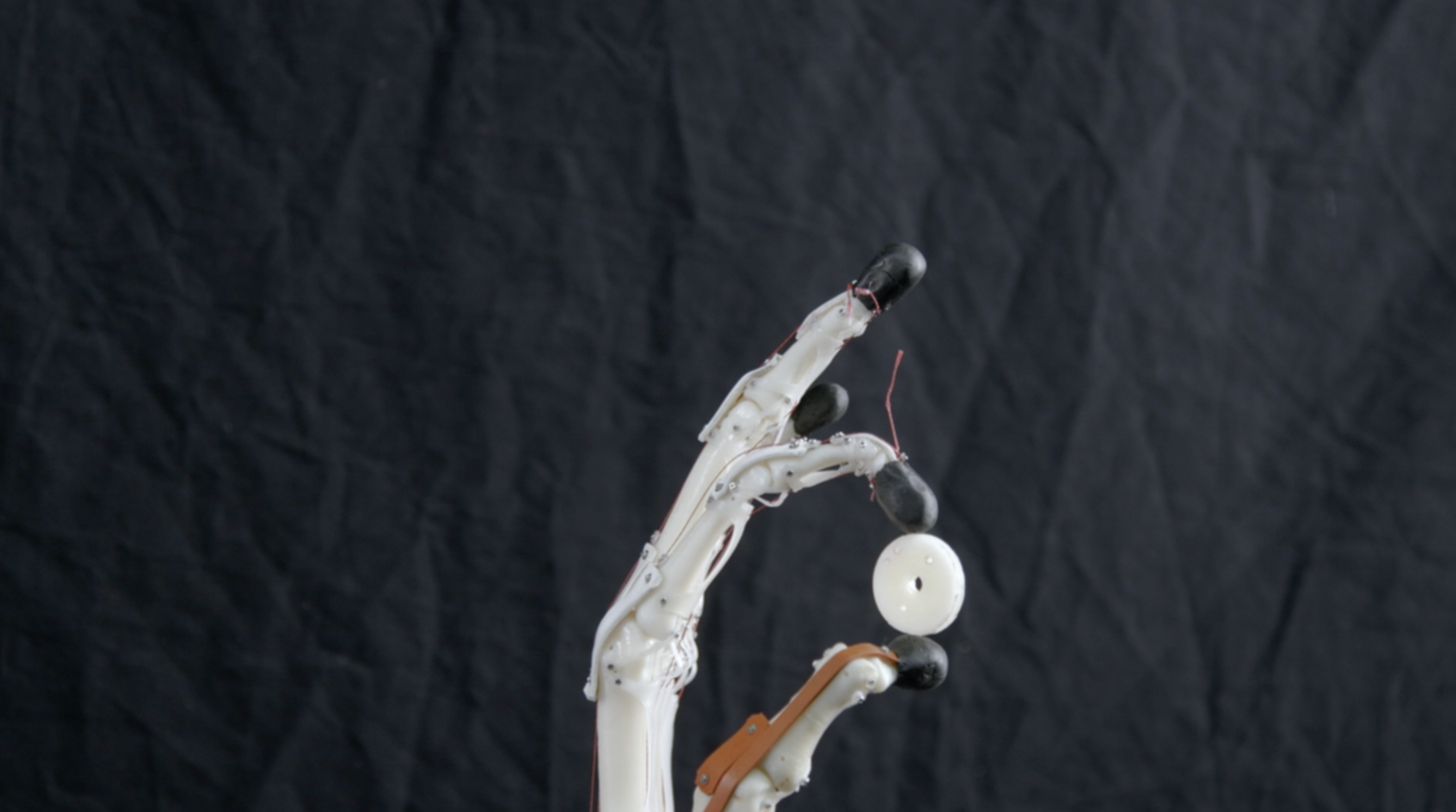

What sets my design apart is its emulation of the human hand’s fundamental components, including bones, ligaments, tendons, tendon sheaths, and intrinsic muscles. By following the natural blueprint of the human hand, I opted for printed ligaments and laser-cut rubber to create joint capsules instead of traditional mechanical joints. This approach significantly enhances the hand’s performance and dexterity compared to conventional robotic hands.

Furthermore, my design closely mirrors the movement patterns of the human hand, enabling me to utilize existing data on human hand movements for control. Rather than writing entirely new code, I employ draw wire sensors to track my actual hand’s movements, transmitting this data to control the robotic hand. This streamlined approach simplifies the software aspect of the project considerably.

Although the physical scale of my robotic hand surpasses human dimensions for ease of manufacturing, the servo motors controlling the hand closely mimic the size of my forearm. This thoughtful design choice optimizes both functionality and aesthetics.

Remarkably, this project is accessible to hobbyist 3D printer enthusiasts. The overall cost, inclusive of motors and other components, remains under $600. Additionally, the entire set of parts can be 3D printed within a mere two days. The bones are crafted from ABS, while the remaining components utilize laser-cut rubber and Taulman’s PCTPE filament. I’ve also incorporated Taulman’s blue Tglase for certain parts, enhancing both durability and visual appeal. The tendons are made from Spectra deep-sea fishing line, ensuring robust flexibility and movement.

It’s important to note that my project draws inspiration from a research paper, which you can explore here: Research Paper. This scholarly work has been instrumental in shaping the innovative approach I’ve taken in designing my biomimetic robotic prosthetic hand.

|

|

|

|

|

|

|

|

|

|